- +91 -7738001457

- contact@kkpengineers.com

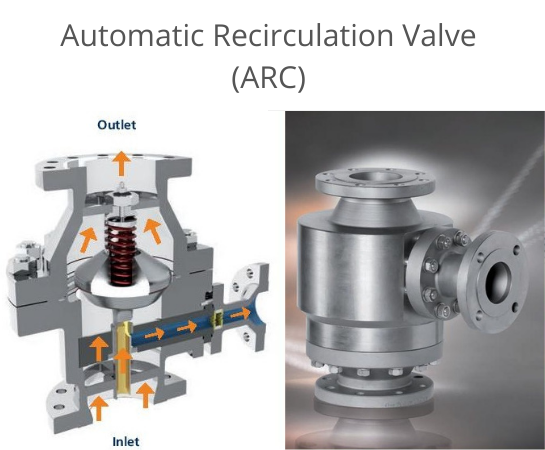

An automatic recirculation valve (ARV) is a multifunctional valve whose primary purpose is to ensure that a pre-determined minimum flow is assured through a centrifugal pump at all times. This is important as centrifugal pumps suffer from overheating and cavitation and can be permanently damaged if they run dry.

Centrifugal pumps transform mechanical energy into pressure energy by means of centrifugal force resulting from impeller rotation acting on the fluid within the pump. The pump requires a minimum liquid flow in order to avoid overheating. If a predefined minimum flow is not maintained, the pump can be permanently damaged.

A safer system is to combine the non return valve, the bypass valve and the control valve into an interconnected unit, the so called “automatic recirculation valve”. This valve closes when there is no flow, automatically opening the bypass line, which is sized for minimum flow. When the main line takes flow but less than minimum, the bypass line and the main line are both partially open. The automatic recirculation valve is therefore a check, bypass, minimum flow and pressure control valve in one body.